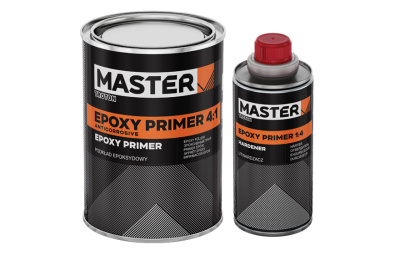

Epoxy Primer 1:1

Imprimación Epoxi Anticorrosiva

Variantes

| Color | Nº art. | Capacidad | Cantidad por caja |

| gris claro | 5432 | 0,5 l | 6 |

| endurecedor | 5433 | 0,5 l | 6 |

Grado de brillo

mate

Documentación técnica

Calculadora de peso/volumen

Video

Descripción

Imprimación epoxi 2K con aditivos anticorrosión. Funciona perfectamente como base aislante para reparaciones de vehículos. Especialmente recomendada para su uso con la técnica húmedo sobre húmedo.

Ventajas

- Excelente protección de superficies de acero.

- Muy buena adherencia a diversas superficies.

- Fácil de mezclar y aplicar.

- Excepcional estabilidad vertical.

Sustratos

La imprimación puede aplicarse directamente sobre:

- Acero y aluminio, después de matizar y desengrasar.

- Acero zincado, acero galvanizado, después de matizar y desengrasar.

- Laminados de poliéster/vidrio lijados (GRP/GRP).

- Masillas de poliéster.

- Imprimaciones epoxi.

- Imprimaciones reactivas.

- Revestimientos antiguos en buen estado después de lijar y desengrasar.

Una buena preparación de la superficie es esencial para obtener los mejores resultados de reparación.

Información importante sobre el uso del producto

desengrasar

Proporción de mezcla

1 : 1

Viscosidad de la ducha

18 ÷ 20s / 20°C

Vida útil de la mezcla

~ 3h / 20°C

1 ÷ 3 capas

HVLP / RP

ø1,2 ÷ 1,6 mm

entre capas

5 ÷ 10 min.

antes de calentar

~ 10 min.

Tiempo de secado

5 h / 20°C

35 min. / 60°C

Proceso de aplicación

Uso

Para reparaciones de automóviles como imprimación aislante para el envío, o técnica húmedo sobre húmedo.

Proporción de mezcla por volumen

Imprimación: 1

Endurecedor: 1

Diluyente: no requiee!Mezclar bien hasta que todo quede homogéneo.

Viscosidad de la ducha

18÷20 segundos a 20°C/DIN4.

Vida útil de la mezcla

Aprox. 3 h at 20°C.

Número de capas

- Para la opción húmedo sobre húmedo: 1,5÷2 manos; película seca de aproximadamente 25÷50µm.

- Para la opción lijado: 2÷3 manos; capa seca 100÷140µm.

Parámetros para pistola:

Boquilla RP: 1,2÷1,6mm; Presión de entrada: 2,0-2,5 bar

Boquilla HVLP: 1,3÷1,5 mm; Presión de entrada: 2,0 bar

Tiempo de evaporación

Entre capas: aprox. 5 ÷10 minutos

Antes de calentar: aprox. 10 minutos

Antes del barnizado (húmedo sobre húmedo): 45÷60 minutosEl tiempo de evaporación depende de la temperatura y del espesor de la película.

Tiempo de secado

Dependiendo del grosor del revestimiento:

- a 20°C – aprox. 5 horas

- a 60°C aprox. 35 minutos

Las temperaturas inferiores a 20°C prolongan considerablemente el tiempo de endurecimiento.

Secado por radiación IR

8÷10 minutos onda corta para 100÷140µm de espesor. No superar una temperatura de 60°C. Utilizar según las recomendaciones del fabricante del equipo. Esperar unos 10 minutos antes de iniciar el secado radiante.

Lijado en seco

Abrasivo: P400÷P500

La versión Mmojado sobre mojado no require lijado!

Lijado en húmedo

Lijado a máquina: P600÷P1000

Lijado manual: P800÷P1000La versión Mmojado sobre mojado no require lijado!

Trabajos posteriores

Las imprimaciones epoxi de 2 componentes pueden aplicarse directamente sobre:

- Barnices de 2 componentes.

- Aparejos de 1 componente.

- Imprimaciones acrílicas de 2 componentes.

- Masillas de poliéster de 2 componentes.

- Masillas de resina epoxi de 2 componentes.

Notas generales

- No sobrepasar la cantidad de endurecedor recomendada.

- Los mejores resultados se consiguen barnizando a temperatura ambiente. La temperatura ambiente y la temperatura del producto aplicado deben ser similares.

- Se recomienda utilizar equipo de protección individual cuando se trabaje con productos de 2 componentes. Proteger los ojos y las vías respiratorias.

- Las habitaciones deben estar bien ventiladas.

- Las herramientas deben lavarse inmediatamente después de la aplicación.

Nota: Para mantener la seguridad, siga siempre las instrucciones de la hoja MSDS del producto.

Haga una pregunta sobre el producto

Productos relacionados

Vasos de pintura graduados

Vasos de pintura graduadosVasos de pintura graduados

Colador para pintura de papel

Colador para pintura de papelColador para pintura de papel

Thinner for Epoxy Systems

Thinner for Epoxy SystemsThinner for Epoxy Systems

Diluyente para sistemas epoxy

C88 Premium Speed HS 2:1

C88 Premium Speed HS 2:1C88 Premium Speed HS 2:1

Barniz

Película protectora

Película protectoraPelícula protectora

Consulte los consejos del producto

Pérdida de adherencia

Defectos de barniz de aplicación|

Pérdida de adherencia

Marcado de bordes (mapeo)

Defectos de barniz de aplicación|

Marcado de bordes (mapeo)

Ver también otros productos

DTM Primer Sealer 4:1

DTM Primer Sealer 4:1DTM Primer Sealer 4:1

Imprimación mutifumcional anticorrosiva

Epoxy Primer 4:1

Epoxy Primer 4:1Epoxy Primer 4:1

Imprimación Epoxy

HS 4:1

HS 4:1HS 4:1

Aparejo acrílico

V2012 HS 4:1

V2012 HS 4:1V2012 HS 4:1

Aparejo de relleno para acero zincado