The repair process

Repair Process II

Part repair, damage or reconstructing of anticorrosion protection using reactive primer

1. Tools needed for the repair

- InterTroton or Master silicone remover

- InterTroton or Master thinner for acrylic products

- Sand paper (for the beginning, for dry) P120-P320, finishing P400-P500 (for dry) P800-P1200 (for wet) for the machine, grindstone, mechanical equipment (see the surface preparation), containers to mix products

- Varnish tape, paper, cover foil to protect a vehicle (parts which are not repaired), antistatic cloth

- Japanese putty knives to apply polyester putty

- InterTroton or Master putty

- InterTroton or Master acrylic primer, for some primers it is better to use a reactive primer to increase anticorrosion protection

- Base coating (colour)

- InterTroton or Master clearcoat

2. Step by step process

Substrate preparation

- On a repaired part, do a thinner test (surface preparation)

- If the result is positive – remove old coating up to bare steel, if negative – you can follow next steps in the process

- Remove dust using compressed air

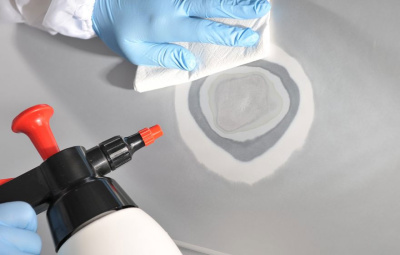

- Clean the repaired part (silicone remover)

- Cover not repaired parts

- Sand a damaged part starting from a sand paper P120 – P180, remove corrosion thoroughly mechanically or manually (see surface preparation)

Reactive primer application

- Using compressed air remove dust

- Clean the repaired part (silicone remover)

- In hard to reach places, internal and external side skirts, underbody and where steel is cleaned from corrosion apply InterTroton or Master reactive primer (according to Technical Data Sheet of a product)

Acrylic primer application

- Then apply InterTroton or Master acrylic primer (according to the Technical Data Sheet of a product)

- After hardening, sand the acrylic primer in a part where polyester putty is to be applied (sand paper for dry P180)

Putty application

- Remove the rest of dust, using compressed air, cleaning with silicone remover (after a thorough remover evaporation)

- Apply polyester putty in two layers with a correct time of drying (according to the Technical Data Sheet of a product)

- Sand the putty with the sand paper P120-P180 at first, finishing with P220-P320

Reactive primer application

- Using compressed air, remove dust, clean with silicone remover (after a thorough remover evaporation)

- Apply reactive primer in sanded places (putty-primer-steel), according to the Technical Data Sheet of a product, the same which was used earlier

Acrylic primer application

- In order to fill and isolate from reactive primer, apply acrylic primer – the same which was used earlier on a repaired part (according to the Technical Data Sheet of a product).

- After hardening, sand the primer with the sand paper P400-P500 (for dry machine or manual), or P800-P1200 for wet (sanding the surface on wet, remember to remove water straight after sanding). We recommend sanding on dry.

Base coat application

- Using compressed air, remove dust and pollution, clean the repaired part and surroundings (silicone remover)

- Cover not repaired parts

- Clean the prepared part with the silicone remover, after evaporation the surface can be wiped with an antistatic cloth

- Prepared base coat apply on the repaired part (according to recommendations of a manufacturer)

Clearcoat application

- After a correct time of base coat drying (see manufacturer’s Technical Data Sheet) (using antistatic cloth, wipe dust or impurities from the surface)

- Apply clearcoat (1,5-2 layers for VHS clearcoats, 2 layers for MS, HS clearcoats), see Technical Data Sheet for using a product

3. Warning!

- Use only original products recommended by a manufacturer

- Follow Technical Data Sheets of a product

- Dry processing of materials is recommended

- During works, use personal protective clothing

- Use IR drying to speed up the drying process of materials

- The temperature and moistness are crucial for products and the repair

- On reactive primer, do not apply polyester products (putties, primers)

Use the products

Silicone Remover

Silicone RemoverSilicone Remover

Silicone Remover

Thinner for Acrylic Systems

Thinner for Acrylic SystemsThinner for Acrylic Systems

Thinner for acrylic systems

15-hole abrasive discs

15-hole abrasive discs15-hole abrasive discs

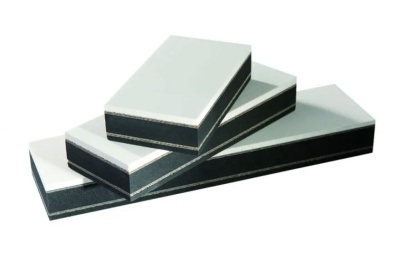

Foam sanding block

Foam sanding blockFoam sanding block

Graduated paint cups

Graduated paint cupsGraduated paint cups

Paint tape

Paint tapePaint tape

Protective paper

Protective paperProtective paper

PE-HD protective film

PE-HD protective filmPE-HD protective film

Flip flop spatulas

Flip flop spatulasFlip flop spatulas

Extra

ExtraExtra

Soft high filling polyester body filler

Hybrid

HybridHybrid

Polyester-epoxy body filler for zinc coated steel

Acryl Filler 5:1

Acryl Filler 5:1Acryl Filler 5:1

Acrylic primer

V2007 HS 5:1

V2007 HS 5:1V2007 HS 5:1

Acrylic primer

Thinner for Acrylic Systems

Thinner for Acrylic SystemsThinner for Acrylic Systems

Thinner for Acrylic Systems

Wash Primer 2:1

Wash Primer 2:1Wash Primer 2:1

Wash primer

See also other articles

Prepare the substrate

The repair process

Prepare the substrate

Repair Process I

The repair process

Repair Process I

Repair Process III

The repair process

Repair Process III