The repair process

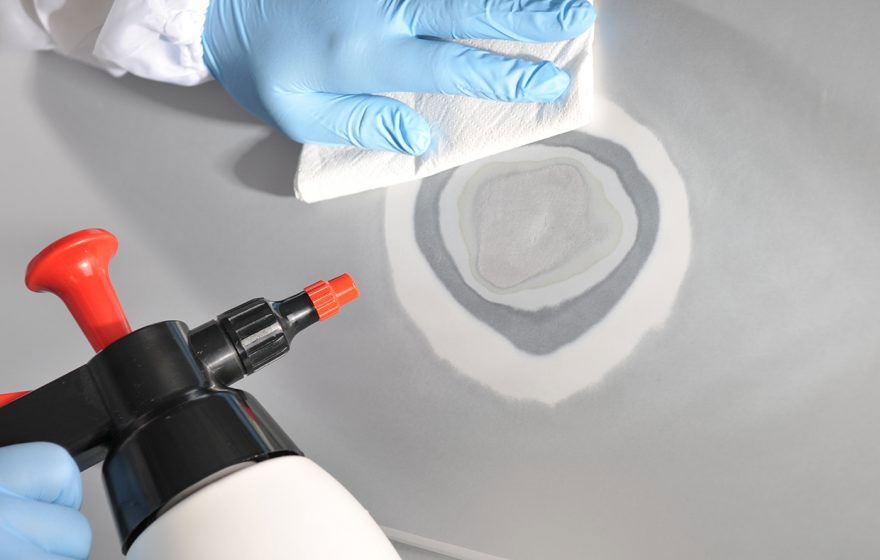

Prepare the substrate

Prepare the repair part and its surroundings

1. Preparing the repair part and its surroundings is a crucial aspect of restoration of the damaged vehicle and the outcome of the repair depends on a few crucial factors, such as:

- Wash a vehicle before the repair

- Remove dust and water thoroughly with compressed air

- Temperature in paint & body shop should not be less than 18ºC

- Temperature of the materials and their application should be similar to the vehicle’s temperature (repaired part)

- After preparation (degreasing and sanding) do not touch the surface with bare hands because it might get polluted with various salts, minerals, grease from human being’s sweat

- Compressed air should be clean and without water, oil. Use sedimentation tanks and air filters

- Paint booths and zones should contain an appropriate bandwidth (check cleanliness of filters)

- Use personal protective equipment for each stage of repair

2. Tools needed for the preparation of the damaged part and sanding materials

Tools can be divided into two groups: manual and mechanical

- Manual: flat, oval, two-sided foam rubber, cork, plastic grindstones

- Mechanical: rotary polishing machine, rotary-oscillatory at various jumps 2,5-3,0 / 9,0-5.0mm, blast abrasive cleaning

Types of sand paper

Sand papers, with various types of graines (carborundum, aluminum oxide (artificial corundum), zircon artificial corundum, abrasive non-woven fabric, abrasive foams, cleaning-abrasive applicators (vinyl, abrasive wheels)

3. A crucial factor is to adjust an appropriate machine to an abrasive material

- A rotary machine in conjunction with a vinyl disc will ideally remove a surface corrosion not fracturing the base structure (steel). Discs are quite elastic and soft.

- The rotary machine in conjunction with the abrasive disc, of P24 or P36 gradation are very aggressive and you have to be careful not to make holes in steel or overheat it.

- The rotary machine in conjunction with foliate (lamella) disc will remove the old coating from the surface.

- The rotary machine in conjunction with a brush disc will remove the old coating not tampering with the surface of steel, it will reach the deeper pores (it operates similarly to a steel brush).

Rotary-oscillatory machines are divided into two groups in the preparation process, coarse and finishing.

- Coarse (jump 9-5 mm), 9 mm are used to prepare the surface in first steps e.g. removal of old coatings, removal of old layers of putty, primers and varnish. 5 mm is used to sand putties.

- Finishing (3-2,5 mm) are used to sand primers (acrylic, epoxy) and matting old paint coatings or to prepare substrate for polishing system.

Use the products

Foam sanding block

Foam sanding blockFoam sanding block

Abrasive discs

Abrasive discsAbrasive discs

15-hole abrasive discs

15-hole abrasive discs15-hole abrasive discs

PE-HD protective film

PE-HD protective filmPE-HD protective film

Paint tape

Paint tapePaint tape

Reusable workwear

Reusable workwearReusable workwear

FFP2 filter mask with valve

FFP2 filter mask with valveFFP2 filter mask with valve

See also other articles

Repair Process I

The repair process

Repair Process I

Repair Process II

The repair process

Repair Process II

Repair Process III

The repair process

Repair Process III